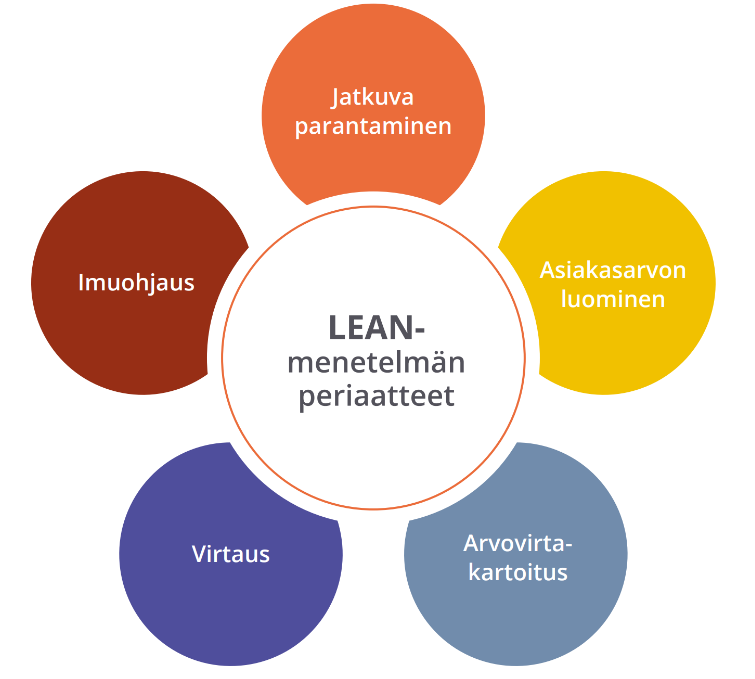

Lean project management is not just a toolbox of efficient processes, but a holistic approach that helps project teams achieve better results with less effort. By focusing on customer value, eliminating waste and continuously improving operations, projects can exceed expectations in terms of quality, efficiency and timelines. Lean principles are worth trying to improve project success.

In this article, I will show how the Lean method helps to focus on the essentials through a fictitious multi-vendor project in the welfare sector.

Text by Päivi Kähönen-Anttila

Creating customer value (Value)

At the heart of lean thinking is identifying value from the customer’s perspective: what is important and useful to the customer in terms of the end result? A common understanding between the client and the team ensures that project activities support the client’s needs and objectives, delivering tangible added value.

In my hypothetical example, we are talking about a project to implement a new patient system, the value of which for end-users is reflected in, among other things, a tangible reduction in manual work as routine tasks are automated. In addition, a more efficient new system will reduce the workload of employees and increase their well-being.

Value Stream Mapping (VMS)

A value stream mapping is a visual tool that describes the steps in a project or the information flows in a system and identifies waste, such as extra steps. It allows both the client and the project team to analyse the process from start to finish. The tool speeds up the project flow and improves efficiency by eliminating unnecessary steps and promoting a common understanding of value.

One concrete application of value stream mapping in healthcare is mapping the patient care pathway and using it to improve service and minimise delays. In a multi-provider project, mapping highlights the need to clarify responsibilities and information transfer between different providers. It helps to identify duplicated tasks, unclear interfaces and delays that can arise when different parties work together.

Flow (Flow)

Once the waste has been removed from the value stream, it is important to ensure that the remaining steps proceed smoothly without interruptions or delays. This requires breaking down siloed thinking and investing in strengthening collaboration between different departments. In projects involving multiple teams or third parties, it is particularly important to ensure that the process runs smoothly. Smooth flow is created by organising work so that tasks flow through the process without unnecessary waiting times.

Projects often involve experts from different teams in the organisation at different stages of the project. Among Lean tools, a Kanban board helps ensure visibility of the progress of tasks. It reduces unnecessary enquiries, clarifies responsibilities and helps identify bottlenecks that slow down the flow. This helps maintain productivity and meet deadlines. Examples of Kanban board software include Planner and Jira.

Suction control (Pull)

Suction control supports the smooth flow by allowing work and resources to be allocated as needed. For example, the just-in-time (JIT) principle ensures that the necessary resources are only allocated when the next stage is ready to receive them. This prevents duplication of effort and wastage.

In practice, this can mean, for example, using a prioritised task list, where tasks are prioritised according to the value they bring and the availability of resources. This allows the project team to ensure a continuous flow and focus on the right tasks at the right time. Close collaboration and clear priorities are key to the success of both flow and suction control.

Continuous Improvement (Pursue Perfection)

Continuous improvement is at the heart of Lean thinking. It is based on small, continuous improvements and the active involvement of all parties. The expertise and ideas of the project team should be supported, as non-traditional solutions can open up new ways of overcoming challenges.

Small, continuous improvements can deliver significant benefits, such as a better user experience, more efficient processes and fewer errors. Problems and errors should be seen as learning opportunities. Continuous improvement is a journey, not a destination. The key is to be open to new ideas and willing to learn.

Lean project management helps you focus on what matters, eliminate waste and deliver value to the customer efficiently. It is not just a process, but a culture of continuous improvement that helps project teams achieve sustainable results.

Author:

Päivi Kähönen-Anttila (MBA) Kumura Oy, Consulting Project Manager

I put a lot of effort into applying Lean principles in my projects on a practical level. My years of experience in various aspects of project management, combined with a continuous improvement drive, help my clients achieve more efficient processes and sustainable value.

This article has been produced as part of a partnership with Kumura Ltd. Read more about Kumura here.